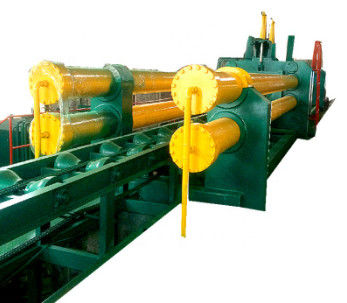

YRT600A ElbowCarbon Steel Hot Forming Machine Elbow Hot Forming Machine

Product Description

| |

YRT125A |

YRT250A |

YRT400A |

YRT600A |

YRT800A |

YRT1200A |

YRT1400A |

|

| processing size range (inch) |

1/2-5'' |

4-10'' |

5-16'' |

8-24'' |

16-32'' |

20-48'' |

20-56'' |

|

| max processing thickness (mm) |

16 |

26 |

41 |

46 |

46 |

46 |

46 |

|

| max pushing power (KN) |

750 |

2000 |

2450 |

4000 |

6100 |

8000 |

11000 |

|

| stroke of main cylinder (mm) |

2500 |

6000 |

6500 |

8000 |

8000 |

10000 |

10000 |

|

| outlook size (M) |

6.6*0.95*1.0 |

14*1.6*1.5 |

15*1.8*2.0 |

19*2.0*2.2 |

19*2.4*2.8 |

25*4.5*3.5 |

25.5*4.8*3.9 |

|

| system pressure (Mpa) |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

| mechanical power (kw) |

11 |

24 |

40 |

54 |

75 |

97 |

105 |

|

| heating power (kw) |

80 |

300 |

400 |

500 |

800 |

1250 |

1250 |

|

| weight (T) |

5.6 |

13 |

17 |

29.5 |

41 |

72 |

105 |

|

Company introduction

Our company produce and export all kinds of carbon steel pipe fittings,Seamless Pipe Fittings, Our city Cang Zhou city is the hometown of carbon steel pipe fittings. We have exported to many countries, such as, Russia, Egypt Malaysia, India, Turkey, Indonesia, Jordan etc.

About the pipe fitting machine, we have different type for every machine.We have hot forming elbow machine, cold forming elbow machine, cold forming tee machine, beveling machine, shot blasting machine, etc.. Machine guarantee is one year. If our clients machine has problem, our after sale service person will come and help the clients solve the problem as quickly as possible.

For JUNXI, we have been in the international leading position in the pipe fitting industry. We have a professional team to provide one-stop service, production, inspection, packaging, and export. HUAWEI is committed to pursuing higher service and better quality. We hope that more partners can achieve a win-win situation.

Elbow Hot Forming Machine

Push machine is the main equipment for the production of elbow, push machine also known as elbow machine, push machine mainly includes the host, hydraulic pump station, operation table, motor control cabinet, if power supply, compensation capacitor, water cable, if coil adjustment frame, reactor.

Push machine is the main equipment for the production of elbow, push machine also known as elbow machine, push machine mainly includes the host, hydraulic pump station, operation table, motor control cabinet, if power supply, compensation capacitor, water cable, if coil adjustment frame, reactor.

The working principle of the push machine: the cut raw material is covered on the core rod of the elbow mold, the intermediate frequency induction wire is set in the end of the elbow mold core, and the cooling water pump and the intermediate frequency power supply are started to heat the raw material to about 800 degrees, and the push machine is started to push the elbow.

According to the pushed elbow, select the main push pump, select the speed of feeding, the gate, manrod heating to the working temperature began to push, push speed can be adjusted in the work, push to the middle point of automatic stop, hydraulic gate, core rod feeding, release the gate back to the end point, gate gate to the outside diameter of the rod began to push. The main push pump can be used at the same time, in general, only one can be used, and it can also be used to back up without stopping. The backward pump can not be used at the same time, with the safety pressure of the hydraulic system of the cylinder set. The travel switch is installed at both ends of the push machine travel, the actual travel should be less than the maximum travel, and the front and rear ends of the movable push plate from the actual end point have a margin, so as not to run the end of the cylinder piston.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!